- ▪ OEKO-TEX certificate.

- ▪ No clogging.

- ▪ No Sticking Powder

- ▪ Good fluency, can be printed continuously for a long time.

- ▪ White ink has high whiteness and strong hiding power.

Brief Information of Hongsam DTF Ink

Brief Information of Hongsam DTF Ink

Brand:JETEXTILE

Colors:C, M, Y, K, W, R, G, B, FO, FG, FM, FY (Fluorescent Color)

Suitable Printheads:Epson I3200,DX5,XP600,TX800......

Applicaton:Suitable for film transfer printing on T-shirts, hoodies, garments, and other type textiles......

What we can offer:DTF Printer, PET film, hot melt adhensive powder (PA、PUD), ink guide liquid, cleaner, printhead protection liquid.

Qualification of Hongsam DTF Direct to Film Ink

Qualification of Hongsam DTF Direct to Film Ink

1. Hongsam Digital is the first drafting unit of national standards for textile pigment inks.

2. Hongsam Digital is the inventor of RCT™ (no pre-treatment and post-treatment needed) printing technology.

3. Hongsam textile pigment ink holds a national invention patent and has independent intellectual property rights.

4.Got approval of the GOTS-7.0.

5. Passed the authoritative ECO PASSPORT certification of the German Hohenstein Institute OEKO-TEX.

6. Passed 201 tests of SVHC substances of very high concern under the EU REACH regulations.

7. Successfully selected into the "10th Batch of Advanced Energy Saving and Emission Reduction Technology Catalog" of China Printing and Dyeing Industry Association in 2016.

8. Won the 2022 China Textile Industry Federation Excellent Patent” Silver Award.

9. Won the second prize of Science and Technology Progress Award of China Textile Industry Federation.

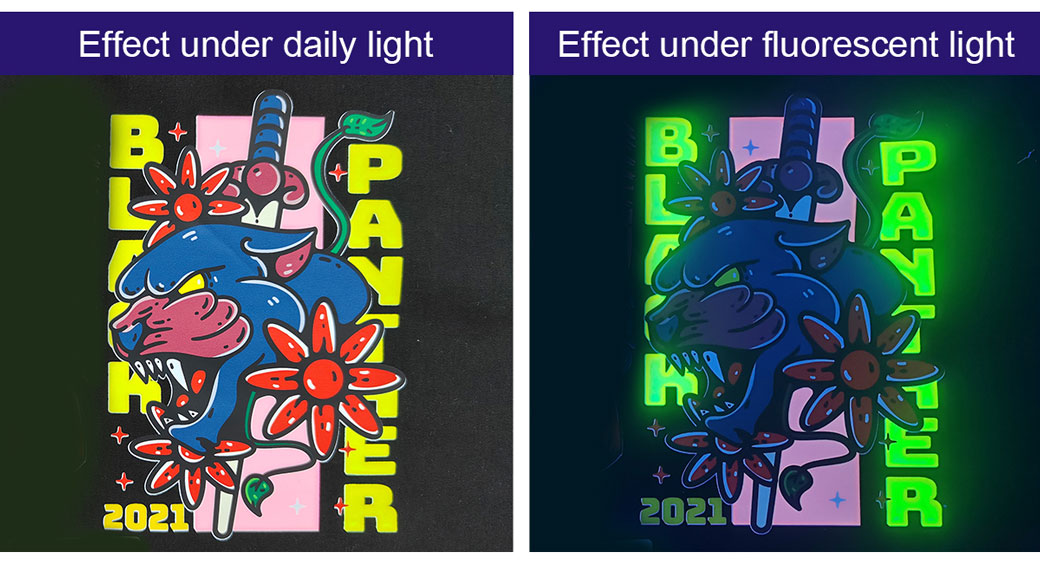

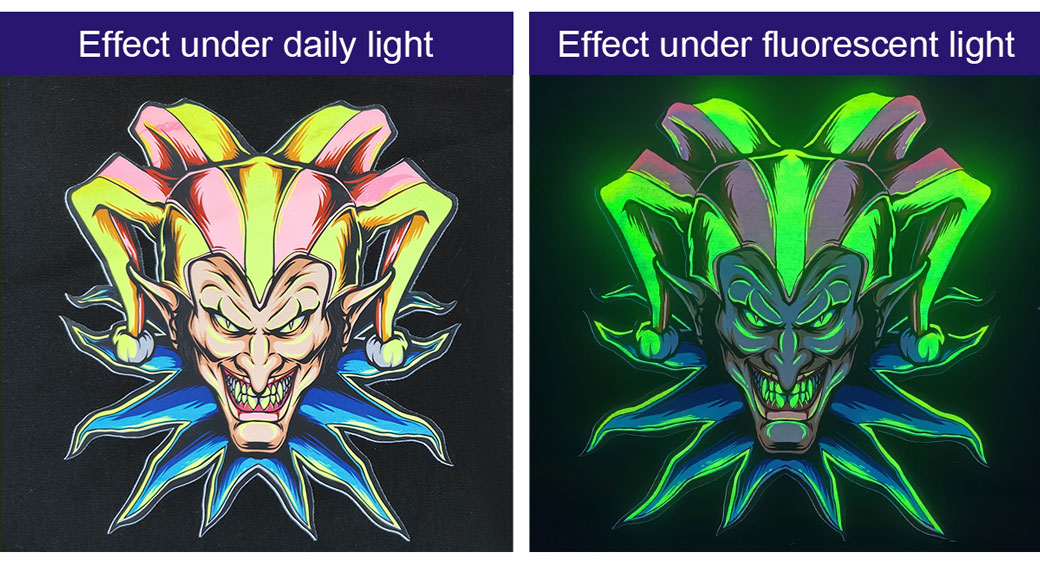

Printing Show of Hongsam DTF Tshirt Printing Ink

Printing Show of Hongsam DTF Tshirt Printing Ink

Color Fastness of Hongsam DTF Film Transfer Ink

Color Fastness of Hongsam DTF Film Transfer Ink

Standard

Type

K

C

M

Y

Washing fastness 60 (ISO 105-C10)

Discoloration

4-5

4-5

4-5

4-5

Staining

5

5

5

5

Rubbing fastness (ISO 105-X12)

Dry rubbing fastness

4-5

4-5

4-5

4-5

Wet rubbing fastness

3-4

3-4

3-4

4

Light fastness (ISO 105- B02)

/

7-8

7-8

7-8

7-8

Development Background of Hongsam DTF Ink

Development Background of Hongsam DTF Ink

In 2020, for the digital printing industry, the term "DTF" continues to be popular. As we all know, the production process of traditional lettering film and film transfer is complicated and inefficient. Digital film transfer has the characteristics of "short cycle and fast delivery". Once launched, it brings a different experience to the personalized customization market. After three years of development, it is now possible to achieve fully automated operation, with a small footprint and simple operation, and has a high market penetration rate.

Textile pigment ink (DTF ink) is suitable for a wide range of materials. It can be said that it is one kind of ink for all fabrics. All fabrics such as cotton, polyester-cotton, polyester-nylon, cotton-nylon, polyester, nylon, silk, etc. can be printed with Jetextile® textile pigment ink (DTF ink).

1. The direct to film (DTF) process is simple and easy to copy, and has strong popularity.

All fashion must be simple and easy to copy. The process of paint heat transfer is that ink is printed directly on the film, color and white are sprayed at the same time, and both dark and light fabric samples can be transferred, which is simple and easy to operate.

2. Low investment threshold and rapid market development.

Film heat transfer equipment (DTF system) mainly includes three major parts: printer, powder shaker, and heat press machine. The overall printing solution cost is low, the investment cost is low. So the whole popularization is developing very fast.

3. Strong flexibility and reduced inventory costs.

In the past, when T-shirts were sold on the market, the finished products often had to be printed in advance and kept in stock. However, now we use the method of heat transfer (DTF printing system). We only need to store the transfer film according to market conditions. When customers place orders, they will be processed into finished T-shirts. In this way It greatly reduces inventory costs and improves capital turnover rate and usage efficiency. Moreover, new products can be launched in a timely manner according to changes in market popular elements at any time to satisfy a broad customer base and meet the personalized requirements.

In order to meet the continuous upgrading and demand of the market, Jettextile DTF ink upgraded again,and the 5th generation DTF ink was lanuched. After continuous improvement, the dispersion and suspension of the DTF ink has been improved, thereby avoiding flocculation, sedimentation, and deterioration caused by long-distance ocean transportation or long-term storage, resulting in customers being unable to use it normally. It solves the common problem of oil return on printed film, improves the feel and smoothness, and is suitable for fast and large-ink printing with multi-nozzle machines. At the same time, the covering power of white ink is improved.

Hongsam DTF Ink Information

01 Suitable for printheads such as Epson I3200, DX5, XP600, TX800 and other models

02 Available colors K/C/M/Y/R/G/B/OR/W

03 Supporting additives including ink guide fluid, cleaning fluid, and printhead protection fluid

Hongsam DTF Ink Characteristics

01 Evenly dispersed, anti-sedimentation for a long time, no flocculation, to avoid sedimentation during export transportation and inability to be used normally.

02 Good leveling, no horizontal lines.

03 White ink has high covering rate, whiter whiteness and good covering power.

04 Good stretchability and soft hand feel.

05 Not easy to be oily, even film formation, no blistering spots.

06 All fastness indicators comply with national or international textile fastness standards.

DTF Film Transfer Printing Process

Why Print Head Clogging Occur?

Print head clogging is the main factor affecting the DTF transfer printing quality and yield. The followings are several major factors that can easily cause print head clogging:

1. Ink quality

Inferior quality ink cannot be used. Ink that is too thick or contains impurities will clog the print head.

2. Ink drying

When the ink dries prematurely in the print head, it will affect the normal ink jetting.

3. lack of maintenance

DTF printing machines is precision machines and require regular maintenance to keep the machine running in good condition. Failure to clean the print head or replace the ink cartridge promptly can cause debris and dried ink to accumulate in the print heads, causing clogging.

4. Environmental factors

When the temperature is too high and the humidity is too low, the ink will dry too quickly, causing the nozzle holes to be blocked and the ink may break. It may also cause the ink itself to evaporate, eventually causing its viscosity to become high and clogging the nozzle.

5. Ink system problems

Problems with the ink system can also cause clogged nozzles. For example, a clogged filter or malfunctioning pump can prevent ink from flowing through the print head.

How to prevent print head clogging

1. Use high quality

DTF ink please use high quality ink that is compatible with your DTF printer.

2. Clean the print head regularly

It is recommended to clean the print head once a week. When cleaning, use a special cleaning solution or distilled water for white ink heat transfer machines, and follow the machine maintenance instructions to do the cleaning work.

3. Use a humidifier

Printing under a working environment humidity between 40% and 60% is best. A humidifier can be used to maintain ideal humidity levels in the room, which can effectively prevent the ink from drying out too quickly.

Will white ink affect the use of print head?

YES!

1. Print head clogged

White ink is thicker and heavier than other inks and can easily cause print head clogging. As the white ink dries in the head, it hardens and prevents other ink from flowing through.

2. Print head damaged

White ink causes greater wear and tear on the printhead due to its thickness and weight. Over time, damage to the print head may occur.

3. Mixed ink

White ink sometimes mixes with other inks in the ink system, causing color contamination and affecting printing quality.