Here are some common issues related to DTF white ink and provide effective solutions to overcome these challenges.

1. Print head clogged

One of the most common problems with DTF white ink is printhead clogging. White ink often contains pigments that settle and dry out, causing clogging. This can result in inconsistent printing, banding, or even no printing at all.

2. Poor adhesion

Another common problem is poor adhesion of white ink to the film. If the white ink does not adhere properly, it may cause peeling or peeling after the transfer process. This is especially problematic when printing on fabrics that require a strong bond.

3. Color output is inconsistent

Inconsistent color output can also be a significant issue. White ink can sometimes appear too thin or too thick, causing changes in color vibrancy. This inconsistency can be frustrating, especially when trying to implement a specific design.

4. Ink separation

Ink separation occurs when the components of white ink separate, causing uneven printing. This can be caused by improper storage, temperature fluctuations, or the use of low-quality ink.

Solutions to Solve DTF white ink problem

1. Regular maintenance of print head To prevent clogging, the printhead must be maintained regularly. This includes performing routine cleaning cycles and using cleaning solutions designed specifically for DTF printers. Also, consider performing regular test prints with white ink to ensure the printhead is functioning properly.

2. Use high quality white ink Investing in high-quality DTF white ink can significantly reduce issues related to adhesion and color consistency. Look for inks that are specially formulated for DTF printing and have a good reputation in the industry. High-quality inks are less likely to clog and provide better adhesion to the film.

3. Optimize printing settings Adjusting printer settings can also help resolve white ink issues. Make sure the ink density is set correctly for the white ink, as too much or too little will result in poor results. Experiment with different settings to find the best balance for your specific printer and materials.

4. Store ink correctly To prevent ink separation, store DTF white ink in a cool, dark place. Avoid exposing the ink to extreme temperatures or direct sunlight, as this may cause components to separate. Also, be sure to shake the ink bottle before use to ensure the pigments are thoroughly mixed.

5. Test printing and calibration Before starting a large print job, do a test print to check for any issues with the white ink. This allows you to identify and resolve issues before they impact the final product. Calibrate your printer regularly to ensure it operates optimally and produces consistent results.

6. Use a dedicated white ink channel If your printer allows it, consider using a dedicated channel for white ink. This helps prevent clogging and ensures that white ink is always available. Dedicated channels also help maintain ink quality and reduce the chance of separation.

7. Monitor humidity and temperature Environmental factors such as humidity and temperature can significantly affect the performance of DTF white ink. Aim to keep the environment in the print area stable, preferably between 20-25°C (68-77°F), with a humidity around 40-60%. This will help ensure that the ink remains in optimal condition.

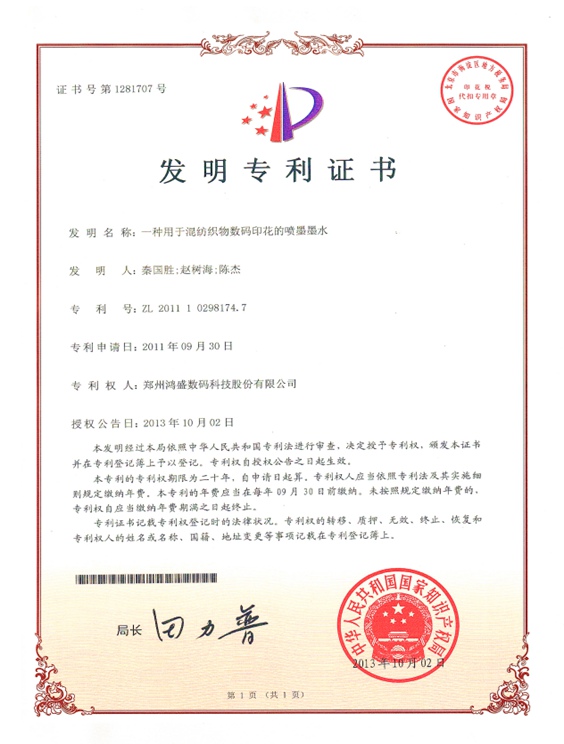

HONGSAM Super White DTF Ink

In order to meet the continuous upgrading and demand of the market, HONGSAM Super White DTF ink was lanuched. After continuous improvement, the dispersion and suspension of the DTF ink has been improved, thereby avoiding flocculation, sedimentation, and deterioration caused by long-distance ocean transportation or long-term storage, resulting in customers being unable to use it normally. It solves the common problem of oil return on printed film, improves the feel and smoothness, and is suitable for fast and large-ink printing with multi-nozzle machines. At the same time, the covering power of white ink is improved.

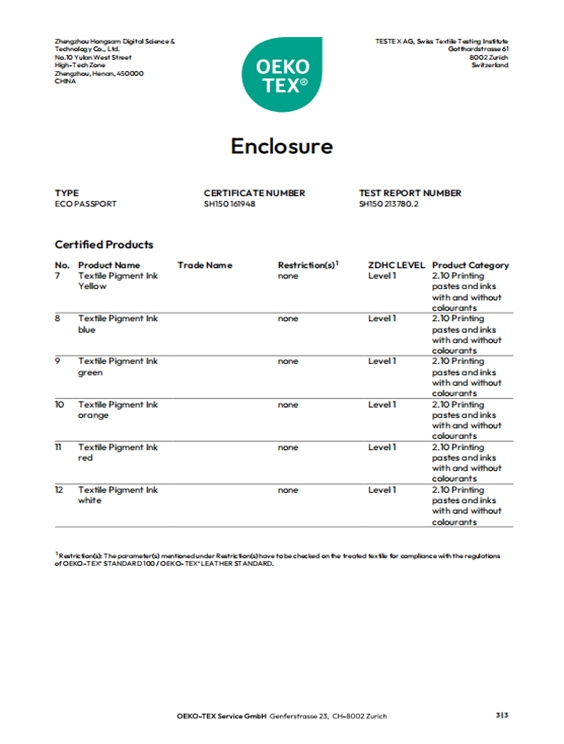

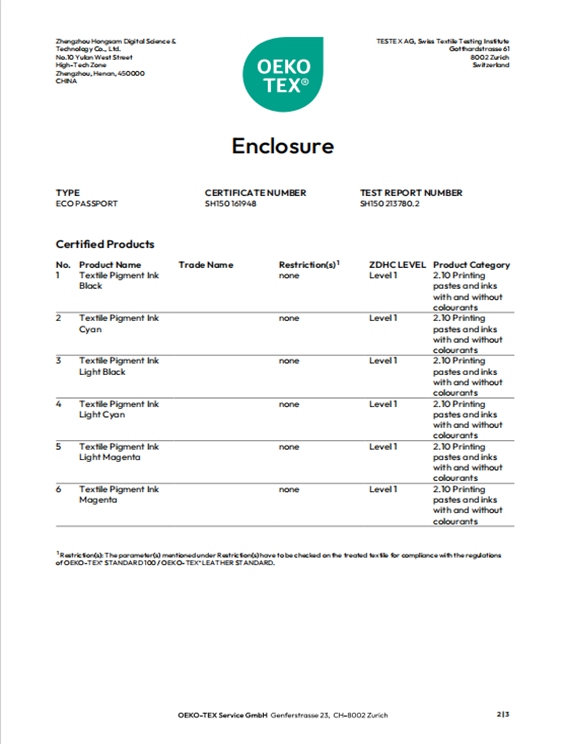

Hongsam DTF Ink Information

01 Suitable for printheads such as Epson I3200, DX5, XP600, TX800 and other models

02 Available colors K/C/M/Y/R/G/B/OR/W 03 Supporting additives including ink guide fluid, cleaning fluid, and printhead protection fluid

Hongsam DTF Ink Characteristics

01 Evenly dispersed, anti-sedimentation for a long time, no flocculation, to avoid sedimentation during export transportation and inability to be used normally.

02 Good leveling, no horizontal lines.

03 White ink has high covering rate, whiter whiteness and good covering power.

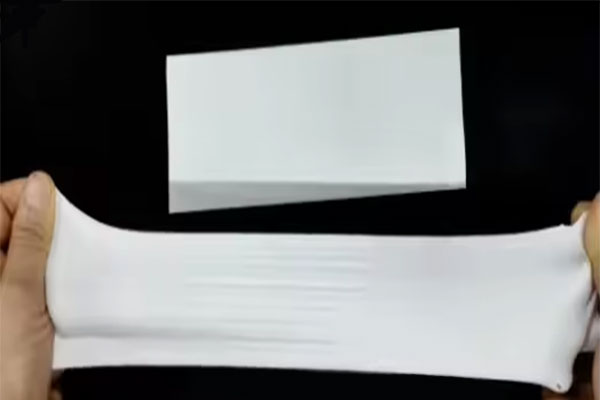

04 Good stretchability and soft hand feel.

05 Not easy to be oily, even film formation, no blistering spots.

06 All fastness indicators comply with national or international textile fastness standards.