Jul 27,2020

Jul 27,2020

Livestream link address:https://v.qq.com/x/page/s312194owxr.html

July 19

Hongsam Digital Live Broadcast Debut

Debuted on time at Hongsam Digital Shanghai Exhibition Hall

Night 19:00

Thousands of spectators flocked to the livestream

We are also very appreciate

《Fashion Print》,《Top Print》and《China Printing Inknet》

Strong support from three media

This time we released it online

Two sets of printing solutions for white ink, 5 types of ink

708A JETTEXTILE® Textile Pigment direct printing color ink (suitable for roll cloth)

708C JETTEXTILE® Textile Pigment direct printing color ink DTG ink (suitable for cutting pieces, ready-made garments, etc.)

TP2000 JETTEXTILE® Textile Pigment direct printing white ink (suitable for Epson Printhead)

TP4000 JETTEXTILE® Textile Pigment direct printing white ink (suitable for industrial Printhead such as Starlight、Ricoh)

TP2600 JETTEXTILE® Textile Pigment DTF Ink

On Site

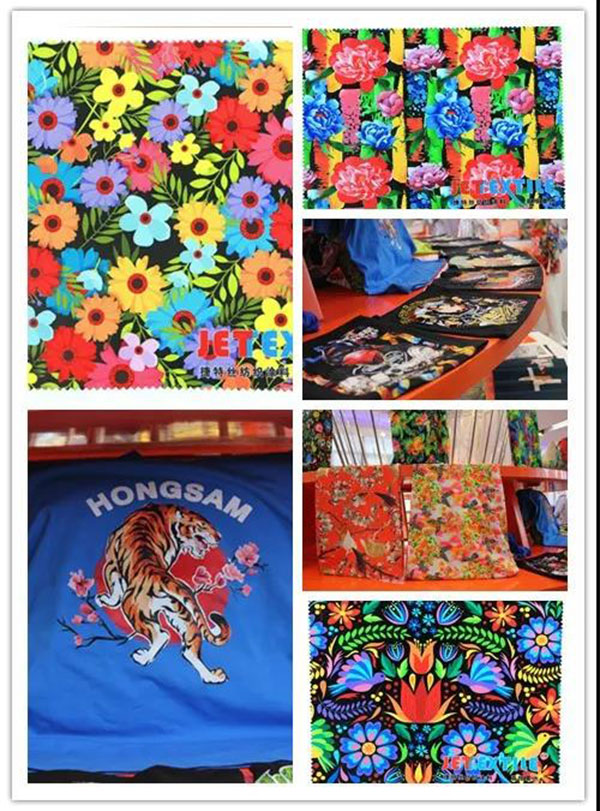

The site not only made a brief introduction to the characteristics of the white ink we released this time, but also showed the wet process of the paint direct injection on the scene, and the printing effect was shocking.

One minute on stage, ten years of hard work off stage

The talk on the live broadcast stage, the obscurity before the live broadcast. Thank you very much to the behind-the-scenes workers who prepared for this live broadcast. Whether it was our preliminary publicity or the day of the live broadcast, everyone was in good condition to show everyone.

Not only are the staff working hard, but the products are also very powerful, which is inseparable from our day and night R&D team and rigorous testing team.

FAQ

In the live broadcast room, we gave a brief explanation of the fastness indicators that customers are more concerned about, and also demonstrated the stretch resistance and scratch resistance of white ink. Especially our on-site printing session gave everyone a more intuitive understanding of Super White.

The technical support is also very good. The knowledge points that we need to pay attention to regarding the white ink printing process are as follows:

Matters needing attention

1. Press the fabric briefly before spraying to flatten the wool.

2. Dark fabric pre-treatment liquid, PP-05, does not need to be diluted. Select the appropriate liquid carrying rate based on the actual situation of the fabric.

3. White fabric pre-treatment liquid pp-03 and 9#a are used in different ways, so please do not confuse them.

4. Transfer to the printing platform, smooth the surface of the fabric, whether it is dry or wet printing, adjust the nozzle and the cloth surface to the appropriate height to ensure the printing quality, and also ensure the safety of the nozzle to prevent scratches on the nozzle.

5. Then pre-dry, put it into the oven after half-drying, and dry at 160℃ for 3 minutes to fix the color.

6. Just a little bit of paint and ink nozzle protection fluid is needed to protect the nozzle. At the end of each work day, inject it into the nozzle protection cap to gently protect the nozzle safety.

7. White ink characteristics: a short white ink cycle before use every day can ensure uniform whiteness output throughout the day without frequent cycles.

8. Film transfer process: distinguish the front and back → print (color first, then white) → pre-bake (100-120°C) → sprinkle hot-melt adhesive powder → dry (hot-melt adhesive powder is baked to a molten state, 150-160 ℃, 2-3min)→hot stamping (150-160℃, 15-20S)→substrate peeling (cold tearing/hot tearing)→finished product.

PET Film transfer printing video:https://v.qq.com/x/page/u3118kkbjsx.html

Thanks for the recognition

This live broadcast is Hongsam Digital’s online debut

The purpose is to provide everyone with an opportunity to communicate and learn online during the epidemic.

Hongsam Digital has always adhered to the business philosophy of "HONGSAM Plus"

Rooted in the inkjet industry, we are willing to establish extensive connections and in-depth cooperation with more companies.

Let’s work together to create a new digital life for humanity!