Apr 17,2025

Apr 17,2025

1. Preface

In the field of digital textile printing, pigment ink printing is an important printing process. It is widely used, simple in process, and environmentally friendly, and is popular among manufacturers. With the rapid development of digital printing technology, pigment ink digital printing has gradually shown its unique advantages.

In terms of technological process, digital pigment ink direct printing does not require tedious steps such as color separation and screen making, which greatly shortens the production cycle; in terms of printing effect, pigment ink digital printing controls the nozzle to spray nano-level dye to obtain high-precision and lifelike patterns with no color limit; in terms of environmental protection, pigment ink digital printing has almost no wastewater discharge, reduces wastewater discharge and chemical use, and is more in line with the concept of green production.

From 2015 to 2023, the total consumption of digital inkjet inks increased from 8,300 tons to 44,350 tons, with an average annual growth of 23.3%. Disperse dye ink accounted for 70% and reactive inks accounted for 15%. With the continuous improvement of pigment digital printing additives and inks, the quality of pigment ink digital printing products has been continuously improved, and they can compete with disperse printing, reactive printing and other digital printing products for market share. In the field of digital inkjet printing, compared with 2022, the market share of pigment ink in 2023 will increase by 0.9 percentage points, accounting for 10.9%.

Although digital pigment ink printing has great advantages, it has not stopped its pace of development. The widely used production process of pigment ink digital printing is now: fabric padding pretreatment → printing → color fixation → finished product. Compared with the reactive ink and disperse ink digital printing processes, this process is already very simple. In order to further optimize the pigment ink digital printing process, reduce costs and improve production efficiency, HONGSAM has launched a pigment ink online sizing pre-treatment solution.

2. Online Sizing Pretreatment Solution Introduction

(1) Good permeability: After printing, the ink permeability is better, which is more helpful for improving the fabric effect, and has a better coverage effect on the fabric hairiness, making the entire pattern effect fuller and brighter.

(2) Energy saving and emission reduction: No pre-treatment and drying process, reducing carbon emissions and reducing drying costs.

(3) Improve efficiency: Further reduce the process and improve production efficiency.

(4) Reduce costs: This solution has a very high color yield, and the same amount of ink can increase the color by 10-40%.

(5) Safe and stable: During the wet printing process, the fluff and dust impurities on the surface of the fabric are covered, avoiding clogging of the nozzle during printing, and improving the stability of the equipment operation.

3. Printing Effect Comparison

1) Color Comparison

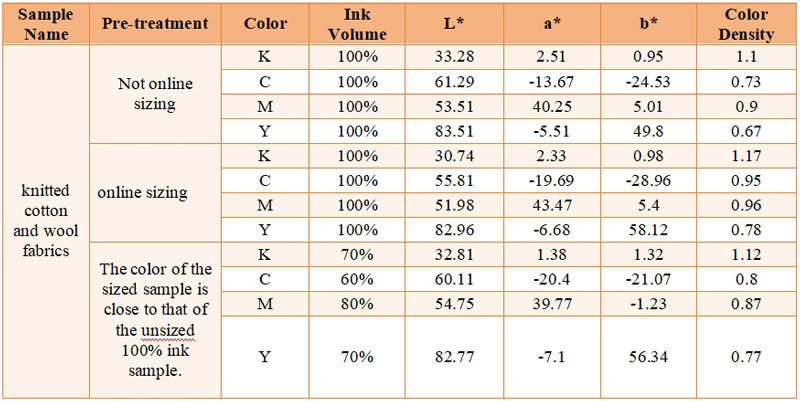

Table 1: Color comparison of knitted cotton and wool fabrics with and without online sizing

From the color value data in Table 1, we can see that after online sizing, the K color depth of the knitted cotton and wool fabric increases by 30%, the C color depth increases by 40%, the M color depth increases by 20%, and the Y color depth increases by 30%.

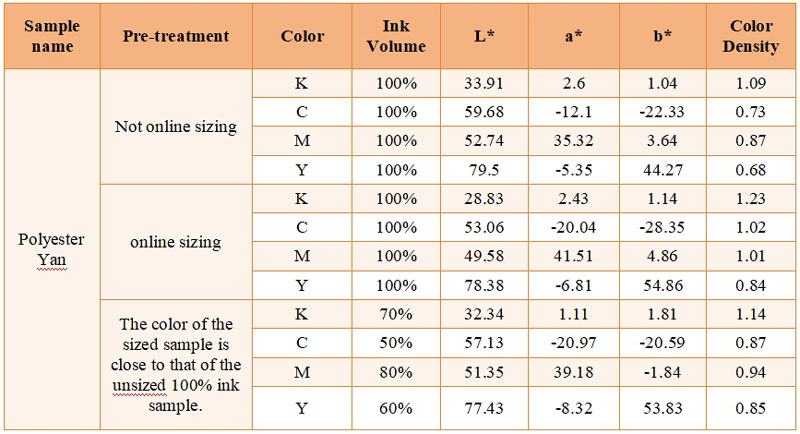

Table 2: Color comparison of polyester yarn with online sizing and without online sizing

From the color value data in Table 2, we can see that after online sizing, the K color depth of the polyester yarn fabric increases by 30%, the C color depth increases by 50%, the M color depth increases by 20%, and the Y color depth increases by 40%.

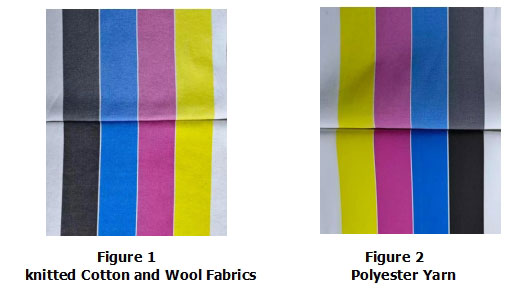

It can be seen from Figures 1 and 2 that on nylon, polyester and cotton fabrics, the color depth can be significantly improved after online sizing.

2) Comparison of Friction Fastness:

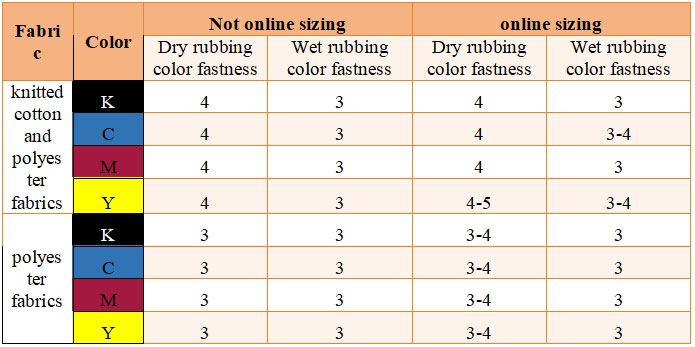

Table 3: Comparison of rubbing fastness of knitted cotton and polyester fabrics with and without online sizing

It can be seen from Figure 1, Figure 2 and Table 3 that after online sizing to deepen the color, the dry and wet friction fastness can still remain unchanged, or even slightly improve.

4. Summary:

As the times develop, people's aesthetic tastes improve, and the demand for personalized clothing continues to increase. The printing and dyeing industry has always been the focus of national environmental protection governance. Therefore, short-process, low-emission pigment ink digital printing solutions will play a more important role in the future textile printing field. As a further optimization of the pigment ink digital printing solution, the pigment ink online sizing solution will surely provide strong support for the development of digital printing.